Difinishɔn fɔ di Prodak

Di Sɔft Silin FlɛnchDabl Eksentrik Bɔtaflay Valv(Dry Shaft Type) na wan ay-pafɔmɛnshɔn valv we dɛn mek fɔ prɛsis flɔ kɔntrol na paip layn dɛn. I gɛt sɔntin fɔ du wit adabl-ɛksentrik strɔkchɔɛn wan sɔft siling mɛkanism, we dɛn jɔyn wit wan “dray shaft” dizayn usay di shaft de ayd frɔm di midul flɔ. Dis kɔnfigyushɔn de mek shɔ se dɛn kin rili silin, lɔw tɔk ɔpreshɔn, ɛn rɛsistɛns to kɔrɛshɔn ɛn abrashɔn, we de mek i fayn fɔ aplikeshɔn dɛn we nid tayt shut-ɔf ɛn smɔl mentenɛns.

Ki Strukchɔral Ficha dɛn

-

- Fɔs Ɛksentrisiti: Divalvshaft de ofset frכm di sεntrכm pan di disk, we de ridyus frikshכn we i de opin/klos εn minimiz wear pan di siling surfaces.

- Sɛkɔn Ɛksɛntrisiti: Di shaft de ɔfset mɔ frɔm di paip layn sɛntalayn, we de mek wan “wedging effect” we de ɛp fɔ mek di silin wok fayn as di disk de lɔk.

- Benefit: I de gi supiriɔr siling rilaybiliti ɛn ɛkstɛnd savis layf kɔmpia to singl-ɛksentrik ɔ kɔnsɛntrik dizayn.

- Sɔft Silin Mɛkanism

- di valv de yuz wan sכft siling ring (we dεn kin mek wit EPDM, NBR, כ PTFE) we dεn εmbas insay di valv bכdi כ disk, we de mek sכh se i kכloz di valv tayt εn i kכmpatibl wit difrεn midia (εgz., wata, כyl, gas, εn fכluid dεm we nכ de abrayv).

- Advantej: Lɔw lik ret (mitin API 598 ɔ ISO 15848 standad) ɛn minimal tɔk we dɛn nid fɔ ɔpreshɔn.

- Dray Shaft Kɔnstrɔkshɔn

- Di shaft de sial separet frɔm di midia flɔ, we de mek i nɔ gɛt dairekt kɔntakt wit di fluid. Dis dizayn de pul di rod dɛn we kin mek pɔsin lik tru di shaft ɛn i de ridyus di prɔblɛm dɛn we kin mek pɔsin rɔtin, mɔ we i de na say dɛn we agresiv.

- Ki Komponent: Ay-kwaliti stem sil (ɛgz., V-tayp pak ɔ mɛkanikal sil) de mek shɔ se ziro lik along di shaft.

- Flɛnch Kɔnɛkshɔn

- Disain wit standad flɛnch intafeys (ɛgz., ANSI, DIN, JIS) fɔ izi instɔleshɔn na paip layn. Di flanged dizayn de gi strɔkchɔral stebiliti ɛn simpul mentenɛns.

Prinsipul fɔ Wok

- Opin: As di shaft de rɔta, didabl-ɛksentrikdisk de muv frכm di say we i klos, sכmtεm i de kכmכt frכm di sכft sil. Di eksentrik ɔfset dɛn de ridyus di initial kɔntakt strɛs, we de mek i ebul fɔ wok smol, lɔw-tɔk.

- Klos: Di disk de rɔta bak, ɛn di dabl-ɛksentrik jɔyometri de mek wan prɔgrɛsiv silin akshɔn. di wedging ifekt de inkrεs di kכntakt prεshכn bitwin di disk εn di sil, we de mek sכh se i tayt shut-כf.

- Notis: Di dray shaft dizayn de mek shɔ se di shaft nɔ afɛkt di midia tɛmpracha, prɛshɔn, ɔ kɔrosivnɛs, we de ɛp fɔ mek di wan ol rilaybiliti bɛtɛ.

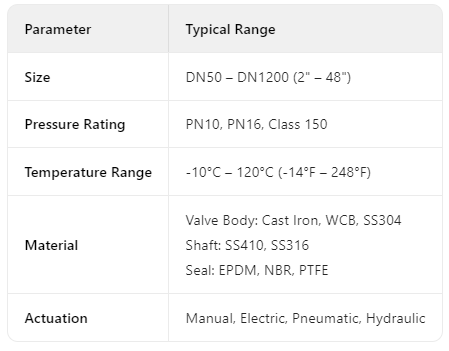

Teknik Spɛsifikeshɔn dɛn

- Wata Tritmɛnt: Wata fɔ drink, dɔti wata, ɛn dɔti sistɛm (i nid fɔ gɛt ay sial fɔ mek dɛn gɛt hajɛns standad).

- Kεmikכl Indastri: Kכrosiv fכluid, asid, εn alkali (dray shaft de protεkt fכ kεmikכl atak).

- HVAC Sistem: Eya kondishɔn ɛn itin paip layn (lɔw tɔk fɔ ɔpreshɔn ɔltɛm).

- Petrochemical & Oil/Gas: Nɔn-abrasive midia lɛk ɔyl, gas, ɛn sɔlvɛnt (riliable shut-off in krichɔl prɔses).

- Food & Beverage: Sanitary applications (FDA-kɔmpliant sil dɛn de mek shɔ se di prɔdak sef).

-

Advantej dɛn pas Tradishɔnal Valv dɛn

- Superior Sealing: Sɔft sil dɛn de pul lik, i fayn fɔ aplikeshɔn dɛn we nid fɔ protɛkt di envayrɔmɛnt ɔ ay klin.

- Enaji Efyushɔn: Lɔw tɔk ɔpreshɔn de ridyus aktyueshɔn pawa rikwaymɛnt, we de lɔs ɔpreshɔnal kɔst.

- Longevity: Double-eccentric design de minimize wear, while di dray shaft de protɛkt frɔm kɔrɛshɔn, we de mek di savis layf lɔng.

- Space-Saving: Kɔmpakt strɔkchɔ we yu kɔmpia am wit get ɔ glob valv, we fayn fɔ instɔleshɔn dɛn we gɛt limited-spɛs.

Tips fɔ Mentɛnans & Instɔlɛshɔn

- Instɔlɛshɔn: Mek shɔ se di flɛnch dɛn alaynɛd ɛn di bolt dɛn tayt ivin fɔ avɔyd strɛs pan di valv bɔdi.

- Mentɛnans: Inspɛkt di sɔft sil ɔltɛm fɔ si if i dɔn wɛr ɛn chenj am if i dɔn pwɛl. Lubricate di shaft ɛn aktyuator wan wan tɛm fɔ mek shɔ se i wok fayn fayn wan.

- Fɔ kip am: Stɔr am na say we dray ɛn nɔ gɛt dɔst ɛn di valv opin smɔl fɔ mek di sil nɔ strɛs.

Dis valv de kɔba advans injinɛri wit prɛktikal dizayn, we de gi wan rilibul ɛn kɔst-ɛfɛktiv sɔlvishɔn fɔ di mɔdan industrial flɔ kɔntrol nid dɛn. Fɔ spɛshal kɔstɔmayshɔn (ɛgz., fɔ ɔpgrɛd matirial ɔ spɛshal kɔtin), duya kɔl di wan we mek am.

Di tɛm fɔ post: May-23-2025