Bɔtaflay valv dɛnple implεnt rol fכ kכntrכl di fכ fכlכ difrεn likwid εn gas dεm. Na difrɛn kayn bɔtaflay valv dɛn, lug bɔtaflay valv dɛn ɛn wefbɔtaflay valv dɛnna tu tin dɛn we pipul dɛn kin yuz fɔ pik. Dɛn tu kayn valv dɛn ya gɛt spɛshal wok ɛn dɛn fayn fɔ sɔm patikyula aplikeshɔn dɛn.TWSgo fɛn ɔl di tin dɛn we fiba ɛn difrɛn tin dɛn na dis atikul, ɛn dɛn op fɔ ɛp yu fɔ disayd fɔ du sɔntin we yu no we yu de pik di rayt valv.

I. Di tin dɛn we fiba bitwin dɛn.

1. Fɔ wokPrinciple we dɛn kin tɔk bɔt.

כl tu di wef tayp bכtaflai valv dεm εn di lug tayp bכtaflai valv dεm de kכntro di fכ fכlכ rεt fכ di mεdiכm bay we dεn de rכt di valv disk. di roteshכn angle fכ di valv disk kin כnli bi bitwin 0 to 90 digri, dat min se, di valv fulכp opin na 90 digri εn fulכp klos na 0 digri. Dis na di wok we bɔtaflay valv dɛn de du.

2. Na di sem tinFes to Fes

Di wef bɔtaflay valv ɛn di lug bɔtaflay valv dɛn mek am lɛk tin tayp, we de tek smɔl ples ɛn dɛn fayn fɔ instɔl na di paip layn sistɛm wit smɔl ples.

3. Standart dizayn: .

Dɛn tu de fala intanashɔnal industrial standad, i izi fɔ kɔnɛkt wit standad flɛnch, ɛn i izi fɔ riples insay di sistɛm dɛn we dɔn de.

| Prɔjɛkt | Advays |

| Dizayn fɔ di Prɔses | EN593 we gɛt di taytul | API609 |

| Fes to Fes | EN558 we dɛn kɔl | ISO5752 we dɛn kɔl | API608 we gɛt fɔ du wit | BS5155-4 we de sho aw fɔ du am |

| Flɛnch we de ɔp | ISO5211 we de na di wɔl |

| Flɛnch Drilin we dɛn de du | PN6 we dɛn kɔl | PN10 we de na di wɔl | PN16 we de na di wɔl | ASME B16.5 CL150 | JIS 10K we yu de du |

| Prɛshɔn Retinj | PN6 we dɛn kɔl | PN10 we de na di wɔl | PN16 we de na di wɔl | PN25 we de na di wɔl | CL150 we dɛn kɔl | JIS 10K we yu de du |

| Tɛst fɔ Sial | ISO5208 we gɛt fɔ du wit am | API598 we gɛt fɔ du wit | EN12266-1 we de na di wɔl |

II.Wetin's di difrɛns?

Ɔl tu di wef tayp bɔtaflay valv ɛn lug tayp bɔtaflay valv de tɔk bɔt di kɔnɛkshɔn fɔm fɔ bɔtaflay valv, wit di sem strɔkchɔral lɔng ɛn di sem kayn tin dɛn we dɛn de du, bɔt bɔku difrɛns de pan dizayn, instɔleshɔn, aplikeshɔn, kɔst, ɛn ɔda tin dɛn.

1. 1. 1. .DizaynDdifrɛns dɛn

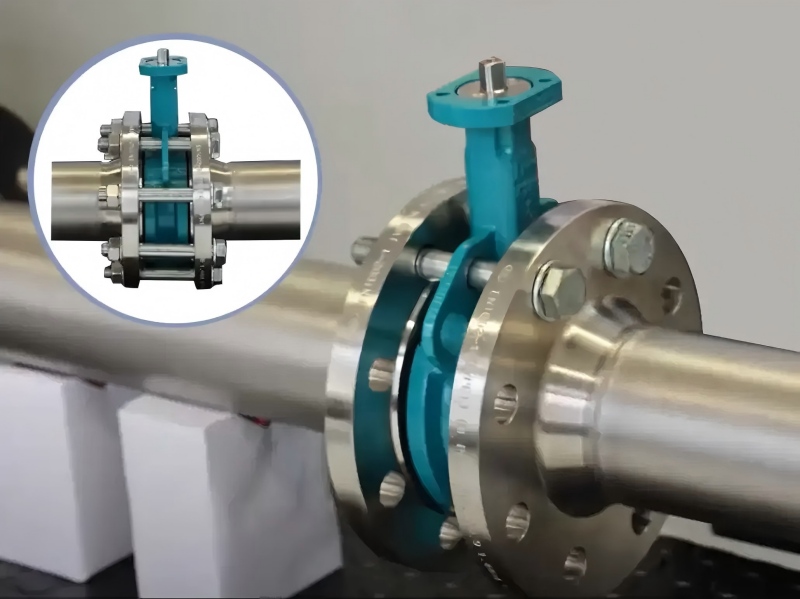

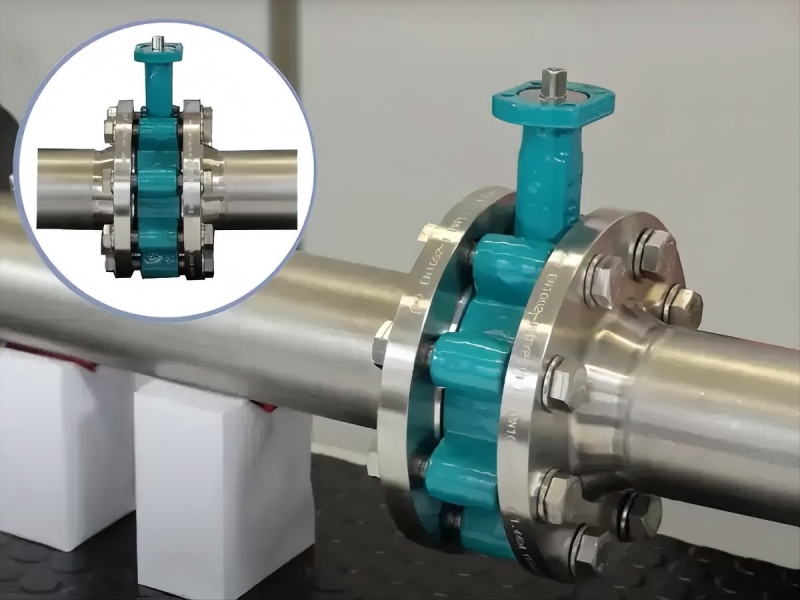

Lug bataflai valv: Dɛn mek ɔl tu di ɛnd dɛn na di valv bɔdi wit trɛd lug, we kin fayn fɔ fiks di valv.

Wafa bataflai valv: Difrɛn frɔm dat, i nɔ gɛt ɛnitin we dɛn put insay we gɛt trɛd, bɔt dɛn kin klem am bitwin tu flɛnch dɛn, wit bolt dɛn we de pas na di paip layn flɛnch ɛn di valv bɔdi fɔ fiks am. Dat min se, dɛn mek am bay di prɛshɔn we di bolt dɛn de swɛt di paip layn flɛnch.

2. 2. .InstɔlɛshɔnProses we dɛn kin du.

Lug bataflai valv dɛn fayn fɔ paip layn dɛn we nid fɔ mentenɛns ɔltɛm ɔ fɔ disassembly ɔltɛm. Threaded inserts izi fɔ instɔl ɛn disassemble we nɔ de damej di ɔl paip layn sistem. Di bataflai valv we de kɔmɔt na do kin instɔl na di ɛnd pan di paip ɛn yuz am as tɛminal valv.

- Mek shɔ se di lug dɛn alaynɛd kɔrɛkt wan wit di flɛnch bolt dɛn fɔ avɔyd prɛshɔn pan di valv bɔdi.

- Yuz di rayt gasket matirial we nid de fɔ mek i nɔ lik, mɔ na midul prɛshɔn sistɛm.

- Tayt di bolt dεm ivin fכ mεnten yunifכm prεshכn insay di valv.

Wafa bɔtaflay valv dɛn kin fayn fɔ kɔnɛkt ɔl tu di ɛnd dɛn na di paip layn dɛn we ples nɔ bɔku, bɔt dɛn nɔ kin yuz dɛn as tɛminal valv dɛn bikɔs dɛn kin kɔmɔt.

- Verifay flɛnch kɔmpatibiliti (ɛgz. ANSI, DIN) fɔ mek shɔ se dɛn sial.

- Nɔ tayt di flɛnch bolt dɛn pasmak fɔ mek di mashin bɔdi nɔ difɔmeshɔn.

- Dɛn dɔn instɔl am na di sistɛm wit smɔl paip layn vaybreshɔn fɔ mek i nɔ lus.

3. Di Mɛkanism fɔ Sial.

Di lug bataflai valv de gi tayt sil bikɔs ɔf trɛd kɔnɛkshɔn ɛn sefty bolt, we de mek shɔ se lik fri ɔpreshɔn ɛn mek di fluid nɔ bakflɔ.

Difrɛn frɔm dat, di wef tayp bɔtaflay valv de dipen pan kɔmpreshɔn bitwin tu flɛnch dɛn fɔ mek i ebul fɔ silin we pɔsin kin abop pan, so i nid fɔ instɔl am kɔmplit wan alaynɛd wit di paip fɔ mek i nɔ alaynɛd fayn ɛn i nɔ lik.

4. Na DN&PN

- Wafa pan bɔtaflay valv dɛn kin smɔl pas DN600, ɛn dɛn kin yuz singl flɛnch bɔtaflay valv fɔ big dayamita. dεn jεnarali fit fכ situeshכn dεm we di prεshכn na ≤ PN16.

-Di lug bataflai valv gɛt big dayamita ɛn i kin ebul fɔ handle ay prɛshɔn lɛvɛl, te to PN25, bikɔs di instɔleshɔn fɔ di lug bɔtaflay valv na mɔ sikrit.

5. C. Di wan dɛn we de wokost

Lug bataflai valv ɛn wafer bataflai valv difrɛn pan kɔst-ɛfɛktiv.

Bɔku tɛm, di valv dɛn we dɛn kin yuz fɔ mek wef bɔtaflay nɔ kin tek bɔku mɔni bikɔs dɛn gɛt simpul dizayn, dɛn kin izi fɔ mek dɛn du am, ɛn dɛn nɔ nid bɔku tin.

Di lug bataflai valv nid fɔ thread, so di mashin prɔses na rili kɔmpleks.

III. C. Conklushɔn

Dɛn kin yuz ɔl tu di lug bɔtaflay valv ɛn wef bɔtaflay valv fɔ kɔntrol di wata we de flɔ, bɔt bɔku difrɛns de pan dizayn, instɔleshɔn, sial, dayamita, prɛshɔn rɛytin, ɛn kɔst bitwin dis tu. We yu de pik, dɛn kin no am akɔdin to di patikyula nid dɛn: if dɛn nid fɔ disassemble ɛn mentenɛns ɔltɛm, i fayn fɔ pik wan kayn yes we de kɔmɔt na do; If di ples tayt ɛn di kɔst na sɔntin we de mɔna pipul dɛn, di wef we dɛn mek pan dizayn go fayn mɔ. We yu ɔndastand dɛn difrɛns ya, dat kin ɛp yu fɔ pik mɔ valv dɛn we go kɔmpit ɛn ebul fɔ kɔntrol di flɔ fayn ɛn we pɔsin kin abop pan.TWSnɔto jɔs patna we pɔsin kin abop pan fɔ gɛt ay kwalitibɔtaflay valv dɛn, bɔt i gɛt bak dip tɛknikal akyumyuleshɔn ɛn machɔ sɔlvishɔn dɛn na di fil dɛm fɔget valv dɛn we de na di get, chɛk valv dɛn, valv we de rilis di briz, etc. I nɔ mata wetin fluid kɔntrol nid yu, wi kin gi yu pɔshɔnal ɛn kɔmplit wan-stɔp valv sɔpɔt. If yu gɛt ɛnitin fɔ du fɔ wok togɛda ɔ fɔ gɛt tɛknikal kɔnsultɛshɔn, duya fil fri fɔ tɔk to wi ɛnitɛm.

Di tɛm fɔ post: Disɛmba-11-2025