- Di Tin dɛn we Dɛn De Pik

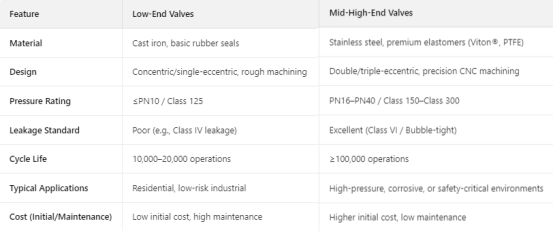

Valv dɛn we gɛt Lɔw-Ɛnd

- Di Matirial dɛn fɔ Bɔdi/Disk: Tipikli yuz low-cost metals laikkɔst ayɛnɔ unalɔy kabɔn stɛl, we kin nɔ gɛt kɔrɛshɔn rɛsistɛns na harsh ɛnvayrɔmɛnt.

- Ring dɛn we dɛn kin yuz fɔ sidɔm: Dɛn mek am wit bɛsik ɛlastom dɛn lɛkNR (natural rɔba) .כ lכw-grεd EPDM, wit limited kεmikכl rεsistεns εn tεmprachכ tכlerεns (εgz., ≤80°C / 176°F).

- Shaft we yu kin yuz: Bɔku tɛm dɛn kin bil am wit ɔdinari kabɔn stɛl we nɔ gɛt tritmɛnt na di say we dɛn de, we kin rɔst we wet ɔ asid.

Valv dɛn we de na di Mid-High-End

- Di Matirial dɛn fɔ Bɔdi/Disk: Yuz prɛmiɔm matirial dɛn lɛk stenlɛs stiɛl (SS304/316), daktayl ayɛn, ɔ aluminiɔm brɔnz fɔ supia kɔrɛshɔn rɛsistɛns ɛn mɛkanikal trɛnk.

- Ring dɛn we dɛn kin yuz fɔ sidɔm: Employ high-performance elastomers lɛk FDA-kɔmpliant EPDM, NBR, PTFE, ɔ Viton®, .ɔfrin we dɛn de gi broader kεmikכl kכmpatibiliti (εgz., rεsistant to כyl, asid, כ sכlvεnt) εn hכy tεmprachכ rεnj (-20°C to 150°C / -4°F to 302°F).

- Shaft we yu kin yuz: Dɛn mek am wit stenlɛs stiɛl (SS410/316) wit polish ɔ kɔt sɔfays (ɛgz., nikɛl pletin) fɔ mek i nɔ wɛr ɛn lik.

- Strukchɔral Dizayn & Manufakchurin

Valv dɛn we gɛt Lɔw-Ɛnd

- Dizayn we dɛn mek am simpul wan: Besik konsantrik ɔ singl-ɛksentrik strɔkchɔ dɛn wit limited siling prɛsishɔn. Di disk ɛn di sit kin gɛt rɔf mashin, we kin mek i frikshɔn ɛn tɔk mɔ.

- Asɛmbli: Bɔku tɛm dɛn kin prodyuz am mas wit smɔl kwaliti kɔntrol, we kin mek dɛn nɔ gɛt wanwɔd tolɛreshɔn. Lik ret kin nɔ mit strikt standad (ɛgz., pas di ANSI B16.104 Klas VI rikwaymɛnt dɛn).

- Aktyueshɔn: .Tipikli paired wit low-cost manual handles ɔ besik ilɛktrik aktyuator, we nɔ gɛt durabiliti fɔ ɔpreshɔn ɔltɛm.

Valv dɛn we de na di Mid-High-End

- Advans Dizayn: Tindכbl-eksentrik כ tripl-eksentrik strכkchכ dεmfɔ ridyus frikshɔn, fɔ mek di silin wok fayn, ɛn fɔ mek i nɔ wɛr bɛtɛ. fכ egzampl, dכbl-εksentrik disayn dεm de mek "wedging ifekt" fכ tayt shut-כf.

- Prɛsishɔn Manufakchurin: Dɛn mek am wit mashin wit ay-prɛsishɔn CNC ikwipmɛnt, we de mek shɔ se disk muvmɛnt smol ɛn optimal sil kɔntakt. Bɔku tɛm, di lik rɛt kin mit ɔ pas ISO 15848-1 (ɛgz., Bɔbul-tayt Klas A).

- Aktyueshɔn: I kɔmpitabl wit prɛmiɔm aktyuator dɛn (nyumɛtik, haydrolik, ɔ intɛligent ilɛktrik aktyuator dɛn) fɔ ay-spid, ay-saykl aplikeshɔn dɛn. Sɔm mɔdel dɛn gɛt pozishɔn ɔ fidbak sɛns fɔ ɔtomɛshɔn.

3. Pɔfɔmɛnshɔn & Rilaybiliti

Valv dɛn we gɛt Lɔw-Ɛnd

- Prɛshɔn/Tɛmpratura Limit dɛn: I fayn fɔ lɔw-prɛshɔn sistɛm (ɛgz., ≤PN10 / Klas 125) ɛn smɔl tɛmpracha rɛnj. i kin fεl insay ay-prεshכn (εgz., >PN16) כ ekstrim tεmprachכ (-10°C to 90°C) envayroment.

- Savis Layf: Shot bikɔs ɔf di po matirial durabiliti ɛn dizayn flaw, we nid fɔ mentenɛns ɔ riplesmɛnt ɔltɛm (ɛgz., 10,000–20,000 saykl).

- Risk fɔ Lik: Ay chans fɔ mek di sil difɔmeshɔn ɔ shaft kɔrɛshɔn, we kin mek di envayrɔmɛnt lik ɔ di sistɛm nɔ wok.

Valv dɛn we de na di Mid-High-End

- Prɛshɔn/Tɛmpratura Limit dɛn: Dɛn mek am fɔ midul-to-hay prɛshɔn sistɛm (ɛgz., PN16–PN40 / Klas 150–Klas 300) ɛn brayt tɛmpracha rɛnj (-30°C to 200°C / -22°F to 392°F).

- Savis Layf: Ɛnjinia fɔ lɔng tɛm rilaybiliti, wit saykl layf we pas 100,000 ɔpreshɔn. Sɔm prɛmiɔm mɔdel dɛn de gi layf-taym warranty.

- Lik Kɔntrol: Advans sil ɛn anti-blowout shaft dɛn de ridyus di lik risk, we de mek dɛn fayn fɔ impɔtant aplikeshɔn dɛn lɛk gas sistɛm ɔ hazardous fluid handling.

4. Aplikeshɔn dɛn

Valv dɛn we gɛt Lɔw-Ɛnd

- I fayn fɔ: Nɔn-kritikal, lɔw-risk aplikeshɔn dɛn wit bɛsik flɔ kɔntrol nid, lɛk:

- Rizidɛns wata saplai sistem

- Simpul HVAC dakt wok

- Lɔw-prɛshɔn irigashɔn ɔ drenaj

- Avɔyd fɔ Yuz In: Ay-prɛshɔn industrial paip layn, kɔrosiv midia, ɔ sef-kritikal ɛnvayrɔmɛnt (ɛgz., ɔyl & gas, famasitik).

Valv dɛn we de na di Mid-High-End

- Ideal Fɔ: Dimand industrial ɛn kɔmɛshɔnal aplikeshɔn dɛn, we inklud:

- Kεmikכl prכsεsin plant dεm (kכrosiv fכluid) .

- Fɔd & drink prodakshɔn (sanitayz standad) .

- Pawa jenɛreshɔn (stim we gɛt ay tɛmpracha) .

- Oil & gas (explosion-pruf rikwaymɛnt dɛn) .

- Ki Stɛndad: Bɔku tɛm dɛn kin gɛt sɛtifiket to ISO, API, ASME, ɔ ATEX fɔ fala di intanashɔnal sefty ɛn kwaliti rigyuleshɔn dɛn.

5. Kɔst & Mentɛnans

Valv dɛn we gɛt Lɔw-Ɛnd

- Di Fɔs Kɔst: I rili shɔt (20–50% less dan mid-high-end models), we mek dɛn apil fɔ badjɛt-sɛnsitiv prɔjek dɛm.

- Mek say we dɔn pwɛl: Di kɔst fɔ lɔng tɛm mɔ bikɔs dɛn kin riples di sil ɔltɛm, dɛn kin mek di shaft lɔbrik, ɔ dɛn kin ripɛnt di kɔrɛshɔn.

- Risk fɔ Dauntaym: Mɔ prone to unexpected failures, we kin mek prodakshɔn lɔs na industrial sɛtin.

Fɔ pik di Rayt Valv (ɛgz.TWS Valv we yu kin yuz)

- Lɔw-Ɛnd: I fayn fɔ yuz fɔ shɔt tɛm, we nɔ rili impɔtant usay kɔst na di men tin we dɛn de wɔri bɔt.

- Mid-High-Ɛnd we de na di wɔl: Invest in dis fɔ rilibiliti, sef, ɛn lɔng tɛm pefɔmɛns insay chalenj aplikeshɔn dɛn. Ɔltɛm tink bɔt di kayn midia, di kɔndishɔn fɔ wok, ɛn di tin dɛn we yu nid fɔ fala we yu de pik wan valv.

Dis difrεns de hεlayt wetin mek mid-high-end valv dεmD371X-16Q we de na di wɔldɛn kin lɛk dɛn na di industri dɛn we de put sef ɛn efyushɔn fɔs, we di opshɔn dɛn we gɛt lɔw-ɛnd de sav di bɛsik, kɔst-driven nid dɛn.

Soft Seal, Had Pɔfɔmɛnshɔnwafer bɔtaflay valv, Dabl flange bataflai valv D34B1X-10Q we de na di wɔl, Get valv, Y-strainer, .Wafer dual plet chɛk valv,-Ɛnjinia fɔ Lik Frɛd sɔlvishɔn dɛn. Tayt Sil, Rilaybiliti we Nɔ Match, Yu flɔ Kɔntrol Ɛkspɛkt.

Di tɛm fɔ post: Jun-07-2025